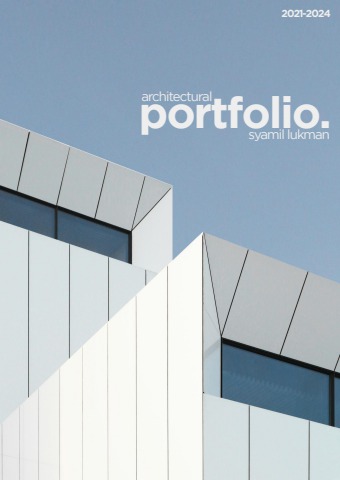

LITHIUM EXTRACTION PLANT & CARGO TERMINAL STATION - DESIGN DEVELOPMENT

Chapter 5.

DORMANT VOLCANO SITE (1) - CERRO TUNUPA, BOLIVIA

51.

52.

53.

54.

55.

LOCAL CITY SITE (2) - UYUNI CITY, BOLIVIA

57.

58.

59.

60.

PROPOSED WIDER MASTERPLAN TIMELINE

END OF CHAPTER.

CARGO TERMINAL STATION - FINAL DESIGN

Chapter 6.

CARGO TERMINAL STATION - UYUNI CITY, BOLIVIA

The Cargo Terminal Station was designed to integrate the city’s grid and existing

site conditions. The one big consideration was to provide a bridge that would link the city, that was previously divided by railways, and extend the boulevard market onto the bridge. The market extension (via bridge) would increase the space in which locals could potentially sell their goods, to the newly arriving tourists, thus boosting lo- cal economy. The facility also holds Lithium Battery Factory, TB Patient Visitors Centre, Cargo Transfer (via gantry), Cablefreight (cable-car) garage/maintenance, cable- way, and new railway stations.

65.

66.

67.

68.

69.

70.

71.

LITHIUM EXTRACTION PLANT - FINAL DESIGN

Chapter 7.

LITHIUM EXTRACTION PLANT - CERRO TUNUPA, BOLIVIA

Lithium Extraction Plant speculates the future, in which the oil is replaced by Lith- ium extraction to meet the ever increasing demand for Electric Vehicles. The oil-rigs

of the past are replaced with new & self-sustained towers that are placed within geothermally heated brine evaporation ponds (pond gardens), which extract lithium-salt from the brine. The L.E.P. then extracts lithium carbonate (used in battery manufacturing) from the lithium-salt. This re- mote industrial facility is also a local health centre for the nearby towns and villages, and a key point for TB patients, as the evaporating salt air (from the brine) engulfs the entire facility and exposes the patients to this man-made phenomena, to which the TB is slowed down and treated.

75.

76.

77.

78.

79.

80.

LITHIUM EXTRACTION PLANT - CERRO TUNUPA, BOLIVIA

END OF CHAPTER.

81.

WIDER MASTERPLAN - FINAL DESIGN

Chapter 8.

PROPOSED WIDER MASTERPLAN OVERVIEW

Proposals in the wider masterplan were designed to work with one another. The cableway infrastructure with Salar Stations, are key to pumping the brine from the Salar, transporting cargo (lithium/salt/ brine), and moving the patients around. The proposed pond garden was designed to speed-up the brine evaporation process, by using small geothermally heated com- partments. L.E.P. then takes over to extract lithium carbonate, and also provide TB treatment facilities for the patients. The car- go is then exported via cableway down

to the C.T.S. where lithium carbonate is used in the Lithium-ion battery factory. The manufactured batteries are then loaded onto freight trains, which transport the goods down to the ports of Chile, and shipped globally.

85.

86.

87.

END OF PROJECT.

The project ‘Saltberculosis - Industrial Lithi- um Retreat’ speculates the future’s shift from fossil fuel to renewable energy, whereby the storage of electric energy is at the centre point of attention. With the rise

in demand for batteries and the lack of them to sustain a global recycle program, the world has to turn to the inevitable - increased manufacturing of Lithium-ion batteries and a different exploitation of natural resources - lithium. The project also explores how this industrial manufacturing process could also aid the 21st Century’s Tuberculosis crisis, in which TB has be- come increasingly resistant to antibiotics.

Salar de Uyuni in Bolivia is the largest un- exploited natural resource of lithium brine in the world. With over 10,500 sq.km. of salt flats, the Salar is also one of the flattest, and at 3,300m above the sea-level, one of the highest points on Earth. The high-altitude, along with bacteria-free air, creates the perfect conditions to slow down the spread of TB within the person. Referencing back

to the pre-antibiotic times, TB was often treated with high-altitude exposure, clean air, sunlight, good diet and rest. The project looks into bringing this historic treatment back and implementing it into an industrial process line.

2018/19

martynas-designs.com

The words you are searching are inside this book. To get more targeted content, please make full-text search by clicking here.

Discover the best professional documents and content resources in AnyFlip Document Base.

Search