step-by-step:

histology

Hs2413A

STUDENT NAME MATRIX NO

FARAH FAIHANA BINTI SUHAIMEE 2020473322

FATIN NUR SYAZWANI BINTI ALIAS 2020834134

NUR ATISYA FARHANA BINTI MAT ZALAMI 2020866392

NUR IFFAH NADIAH BINTI ILIAS 2020819734

NURUL NAZIRAH BINTI RUSMAN 2020621516

SITI NURZAKIAH BINTI JA’AFAR 2020846784

PREPARED FOR : - MADAM HARTINI YUSOF

- DR. NUR AYUNIE BINTI ZULKEPLI

DATE OF SUBMISSION : 5 JANUARY 2022

Farah & Nadiah Atisya & Syazwani

Introduction FLOW CHART OF GENERAL

PROCEDURE

Histology is the study of tissues and their structure. TISSUE

It helps in diagnosis and surgery in hospitals as GROSSING

treatment for patients. This is because some TISSUE

diseases will affect tissue patients such as cancer. PROCESSING

Histological technique starts from grossing,

processing, embedding, sectioning, staining, TISSUE

mounting and labelling. Furthermore, the frozen EMBEDDING

section is also part of histological technique. This

method is commonly used to examine tissue TISSUE

surrounding tumors under a microscope. Therefore, SECTIONING

this can allow surgeons to make great decisions for

surgery. A section of tissues will be cooled rapidly TISSUE

using cryostat and cut into microscopic sections. STAINING

However, with the advanced technology of

histological techniques, there are still challenges in

utilization of this technique in histotechnology lab.

Some of the addressed challenges are shortage of

qualified histotechnologist, increasing influx of more

sophisticated specimen testing. The differences in

standardization of testing processes and results

also complicates the continuity of a histotechnology

lab efficiency. The improved technology may give

more precise and accurate results, but they also

cause increase demands on labs. In facing the

challenges that arise, some initiatives have been

taken to counterbalance the challenges such as

companies that can provide products and services

for histology testing. These challenges are not all

problematic and negative but somehow it creeps

the way up to technologist that may complicate and

push them off their limit.

SLIDE 1

MOUNTING &

LABELLING

Flow chart 1: Flow chart of general procedure histology

tissue grossing Zakiah

Principle

1.The samples and the requisition must have the same cassette number.

2.To avoid inhaling formaldehyde fumes, the grossing station must be sufficiently aired. Ensure to wear

personal protective equipment.

3.To avoid mix-ups, only one specimen container should be opened at a time while grossing.

material procedure

Human tissue specimens (fixed with Personal protective equipment (PPE) was

commercially prepared 10% formalin) worn to avoid hazards.

Apparatus The cassette was labeled according to the

type of specimen, student name, student ID

1. Scalpel holders

2. Scalpel blades number and date by using a pencil.

3. Forceps

4.Tissue cassettes The grossing workstation was prepared.

5. Containers The grossing station fume hood switch was

6. Rulers

7.Dissecting boards turned on. The apparatus were ensured

8. Medisheet ready to be used.

9. Gloves

10.Lab coat The specimen grossing was performed

11. Masks one at a time. Ensure the size of the

12. Goggles specimen fits with cassettes (below 4 cm).

equipment Tissue cassette was placed into 10%

Neutral Buffered Formalin.

Ducted Fume Hood: Iryas

result Figure 1: Fume hood as working area Formalin waste was discarded into the

for grossing procedure formalin waste container.

Tissue blocks

Flow chart 2: The procedure of tissue grossing. WASTE

conclusion

The fixed tissue specimen was trimmed into

small blocks successfully.

Figure 2: The flow of putting tissue blocks in cassette. SOLUTION

Problem Replace the tissue and gross the tissue according

to the size that can fit the cassette.

Tissue samples were too small, causing

difficulties to gross the sample.

Table 1: Troubleshooting of tissue grossing 2

Nazirah

tissue processing

Principle

1.Tissue specimens are prevented from parenchymal damage and distortion by

removing all extractable water from the tissue specimen to enable it for tissue

sectioning.

2.This process will provide a rigid medium that will support tissue sectioning.

material procedure

Fixed tissue blocks (10% formalin) A)Chemicals/Reagents Preparation

Apparatus Various concentrations of alcohol are prepared as follows.

1. Forceps 1. 50% Alcohol (2.0L):

2. Gloves 1000 ml of Absolute Alcohol added to 1000 ml of distilled water

3. Aprons

4. Masks 2. 70% Alcohol (2.0L):

5. Goggles 1400 ml of Absolute Alcohol added to 600 ml of distilled water

3. 80% Alcohol (2.0L):

1600 ml of Absolute Alcohol added to 400 ml of distilled water

4. 95% Alcohol (2.0L):

1900 ml of Absolute Alcohol added to 100 ml of distilled water

5. Alcohol and Xylene mixture (2.0L):

1000 ml Absolute Alcohol added to 1000 ml Xylene

B) Tissue processing

All the reagents are placed in the automated tissue processor and

time was set according to the table below.

equipment

Automated Tissue Processor:

Shandon Citadel 1000

Tissue Processor Table 2: The time setting of each reagent in tissue processing. Source from laboratory

manual UiTM Puncak Alam.

Figure 3: Machine tissue processor.

Total processing time = 21 hours

Problem Full program time = 21 hours 11 minutes, allowing one (1) minute for every change of position

result

Processed tissue blocks

conclusion

Tissue is successfully processed when the processing

step is not under or overtime processed.

solution

Tissue is coming out from the cassette because Tissue should be properly cut

tissue is too small during grossing

Overtime dehydration can cause folded and Ensure the time of processing is correct.

cracked tissue sections.

Table 3: Troubleshooting of tissue processing 3

Iffah Nadiah

tissue embedding

Principle

1.Enclosing tissues or specimens in a mass of embedding media using a mould.

2.The tissue blocks require a supporting media in which to be embedded because they are so

thin in thickness.

3.Embedding medium is used such as Paraffin wax, celloidin, synthetic resins, gelatin, and other

embedding materials are used.

material procedure

Processed tissue blocks 1.The tissue embedding machine is to be confirmed as containing a

molten paraffin tank and it exceeded the melting point of paraffin

Apparatus wax, within 54°C - 60°C. If necessary, the paraffin wax will be

added into the tank.

Forceps Tissue paper

2.Processed tissue cassettes are placed into the cassette holding

Scraper Gloves tank.

Steel block mould Apron 3.Cryo console or Module will be turned on.

4.Tissue Embedding Centre light also is turned on.

Gauze Mask 5.Cassette opened to view the tissue sample.

6.The best mould that corresponds to the tissue sample will be

reagent

chosen.

Paraffin wax 7.A small amount of molten paraffin will be added into the mould.

8.Using warm and clean forceps, processed tissue from the tissue

equipment

cassette will be transferred into the mould facing downward the

Paraffin Tissue Embedding Centre: Slee cut surface. The tissue will be orientated accordingly.

Mainz MPS/C MPS/P MPS/W (11 11 0811/ 9.The mould will then be transferred into the cold plate. Using warm

G1 11 0791/ HAI 11 0802) and clean forceps, the tissue will be pressed flat gently and firmly.

10. Labelled cassette will be placed on top of the cassette.

Figure 4: Machine tissue embedding. 11. Mould will then be filled with molten paraffin until it is fully

covered. Forceps are wiped with clean tissue paper or gauze.

result 12. A labelled paper will be placed on top of the cassette. The mould

will then quickly cool down on the cryo console.

13. The paraffin will be separated from the mold after the paraffin wax

solidifies.

14. Excess wax from the paraffin tissue block cassette will be

removed using a scraper.

15. The used mould will then be placed into the mould tank.

16. Following the completion of tissue embedding, paraffin wax will be

added into the tank if it is near to empty.

17. Cryo console and light is switched off. Workbench and floor is

cleaned from excess wax

Paraffin blocks

Figure 5: Paraffin block after done in embedding step.

conclusion

Tissue block is successfully embedded in molten wax

and ready for tissue sectioning.

Figure 7: The flow of embedding procedure

Problem solution

Double layer of block specimen due to

overtime during positioning the tissue Tissue should be embedded properly

especially during positioning.

causes the split of the block.

Too much pressure during putting the specimen in Give the adequate amount of pressure during

putting the tissue in molten wax.

molten wax can cause the crack of the block

Figure 6: Crack paraffin block (figure 6) 4

Table 4: Troubleshooting of tissue embedding

t i s s u e s e c t i o n i n g FarahFaihana

Principle

1.Tissue section should be cut very thin, about 3-4 microns.

2.Ensure the tissue section does not have air bubbles, folds and wrinkles to avoid picking up additional stains.

3.Thick tissues section can make interpretation more difficult because it will take up additional stains.

material procedure

Paraffin blocks A. Setting up microtome

1.Microtome was turned on

2.The fixing lever was adjusted for the orientation of the

specimen

3.Blade angle was set to 90° and the microtome blade was

Apparatus inserted

1.Slide racks Figure 8: Paraffin blocks after 4.Handwheel lock was released

2.Clean frosted end glass slides embedding process Figure 12: Setting up microtome

3.High profile microtome blades

4. Scraper B. Trimming

5.Clean brush 1.The tissue block was placed onto the standard object clamp.

6.Clean gauze 2.M button was pressed until the ‘Macro’ word appeared and set

7. Paper the trimming thickness to 10 microns

8.Tissue paper 3.The motorized advance button was pressed to adjust the

9.Pasteur pipettes specimen block towards the blade.

10.Applicator sticks 4.The protection guard was removed.

11. Pencils 5.The complete tissue was trimmed until the tissue ribbon

12.Biohazard bags appeared. (Figure 13)

6.The trimmed paraffin blocks were cooled in freezer at -20°C.

7. The used microtome blade was changed with a new blade. Figure 13: Tissue ribbon

after trimming

equipment Figure 9: The apparatus and equipment for C. Sectioning

tissue sectioning 1.Microtome blade was inserted and the blade fixation was

tightened.

1.Rotary microtome: Slee Mainz CUT5062 2.Handwheel lock was released for cutting.

3.Tissue block was placed on the standard object clamp

2.Tissue floatation bath: XH-1001, Thermo 4.M button was pressed until the ‘Macro’ word disappeared and Figure 14: Fishing the

set the section thickness to 3 microns. best section of tissue

Scientific 3120058 5.The position of tissue block was adjusted. ribbon sectioning

6.The paraffin tissue block was sectioned until it produce ribbon

3. Freezer sections

7.Applicator stick or forcep was used to pull the ribbons from

4.Oven: Memmert Figure 10: Rotary microtome the blade

8.The ribbons sections were transferred and laid into the

result flotation water bath filled with distilled water (45°C).

9.The best section was selected and separated from others by

using an applicator stick.

10.Fishing was performed onto the glass slide and placed on the

slide rack to remove water (room temperature). (Figure 14)

11.Slide was labeled with the student's name and ID number on

the frosted end of the slide before placing it in the slide rack

Tissue sections D. Cleaning process

1.The microtome handle was locked after the sectioning process

conclusion Figure 11: Tissue sections as the result of was completed. The blade was removed and disposed of in a

tissue sectioning sharp container.

2.The microtome was cleaned using paraffin repellent.

3.The microtome was switched ‘Off’ and covered with a plastic

cover

4.The floatation bath was turned ‘Off’ and cleaned using a sponge.

Tissue block was successfully cut into thin E. Drying oven time and temperature

sections, placed on the slide and next 1.37 C for overnight

ready to be stained 2.58 - 60 C for 15-30 minutes

Problem Flow chart 3: The procedure of tissue sectioning Figure 15: Oven

for heating the

Solution tissue section

The tissue section is compressed Cool the tissue in freezer.

Inconsistent temperature of floatation bath resulting Fix the temperature of the water floatation bath

wax to melt at 45°C.

Blunt blade hardens the trimming and sectioning

process Replaced the blunt blade with a new

one.

Table 5: Troubleshooting of tissue sectioning 5

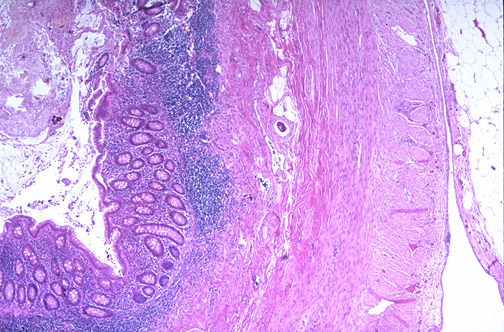

tissue staining Atisya

Principle

1.The chemical affinity between tissue and dye is the basis for H&E stain.

2.On basophilic structures, such as chromatin, ribosomes, and cytoplasmic areas rich in RNA,

hematoxylin, a basic dye, imparts a blue-purple contrast.

3.The basic constituents, such as RBCs, cytoplasm, muscle, and collagen, are counterstained in

increasing intensities of pink, orange, and red by an acidic eosin.

material procedure

1.Unstained tissue slides Prepare various concentration of alcohol as follow:

95% Alcohol (250 ml):

Apparatus 380 ml of Absolute Alcohol was added to 20 ml of

distilled water

1.Slide racks Tissue staining

2. Forceps 1.The unstained slides were removed from the oven.

3.Filter paper 2.The slide was stained in a fume hood, according to the

4.Tissue paper procedure below:

5. Funnel

6.Measuring cylinder

7.Tripod stand

REAGENT

1.Hematoxylin 3G (Sakura) - Commercially

prepared

2. Eosin (Sakura) - Commercially prepared

3. Xylene

4.Alcohol (Absolute, 95%)

5.Distilled water

6.Tap water

equipment Total staining time =

33 minutes.

1.Oven: Memmert

c o n c l u s i o nfTroamblela6b:orTahtoertyimmeasneutatilnUgiToMf ePacuhncreaakgAelanmt for tissue staining. Source

2.Hotplate & Stirrer: Pro, HP-7 Lab Plus

The tissue section was successfully stained

Series Figure 16: Hotplate & stirrer using haematoxylin and eosin.

result Solution

Stained tissue slides Stain the slide in each reagent in the right duration

that has been given.

Figure 17: Stained tissue slide after

H&E staining.

Problem

Overstaining the slide.

Misplaced arrangement of the reagent. Label the container of the reagent by numbering.

Table 7: Troubleshooting of tissue staining 6

Syazwani

slide mounting & labelling

Principle

1.The mounting media is the solution in which the specimen is immersed, usually behind a

coverslip.

2.The major objective of mounting media is to protect the specimen physically; the mounting

medium uses a clear durable film to glue the specimen, slide, and coverslip together.

3.Xylene was used as a glue to make sure the specimen was preserved under the coverslip.

material procedure

1.The task should be performed in a fume

1. H&E-stained slides hood.

Figure 18: Stained tissue slide after 2.Appropriate coverslip was chosen according

H&E staining

to the size of the tissue section. Figure 22: Fume hood

3.Adequate mounting medium was placed on

reagent one edge of the slide.

1. Mounting medium 4.The coverslip was gently lowered until it

(CoverSeal-X)

touched the mounting medium. The mounting

2. Xylene

medium will flow outward and carry the

coverslip along with it because of capillary

attraction.

Figure 19: CoverSeal-X 5.Ensure there are no air bubbles. If air bubbles

were present, the coverslip was gently

Apparatus pressed with an applicator stick to remove Figure 23: Using

them but if too many were present, the slide applicator stick to avoid

in xylene was placed to remove the coverslip bubbles

1. Slide racks and the mounting procedure must be

2. Coverslip (22 X 40 mm / 24 X 60 repeated.

mm) 6.Slides were labelled with type of specimen,

3. Gauze staining method, student name, student ID

4. Forceps number, and date.

5. Applicator stick Figure 20: Slide racks 7. Sticker label was placed at the frosted end of Figure 24: The result

6. Coplin jar the slide. after done mounting

and labelling

7. Self-adhesive labels sticker

result

H&E-stained slide

Figure 21: Coverslip

equipment conclusion Figure 25: The result

of stained tissue

1. Ductless Fume Hood: Esco slides after mounting

and labelling

The tissue section was successfully mounted with

a coverslip using a mounting medium.

The stained slide was labelled clearly with

specimen and stain details.

Problem solution

Air bubbles present under the coverslip. The coverslip was gently pressed with an

applicator stick to remove them but if too

many were present, the mounting procedure

need to be repeated.

The slides were not dried well. Use a hair dryer to speed up the drying

process.

Table 8: Troubleshooting of tissue mounting and labelling 7

Frozen section

Principle

1.The temperature in cryostat usually 0⁰C to -35⁰C. Tissue can be Fsiegcutrieon26m:aTcishsinuee frozen

sectioned in -15⁰C to -25⁰C.

2.Tissue is frozen beacuse water in tissue become ice.

3.Ice will act as embedding media

material procedure

1.Fresh tissue A. Preparation of chemical / reagents

1.95% Alcohol (400 ml) was prepared by adding absolute

reagent

alcohol to 20 ml of distilled water.

1.Tissue freezing medium B. Tissue sectioning

2.10% neutral buffered formalin 1.The temperature of the cryostat was set up to -20°C.

3.Hematoxylin 3G (Sakura) 2.Forceps, low profile microtome blade, brush and applicator

4.Eosin (Sakura)

5. Xylene sticks were placed in the cryostat

6.Alcohol (95%) 3.10% formalin in coplin jar was put in the oven at 60°C one

7.Distilled water

8.Tap water hour before using for the specimen.

4.The specimen was grossed.

Apparatus 5.Then, tissue was embedded on a specimen disc with Tissue

1.Clean glass slide Freezing Medium.

6.The tissue was freezed in the cryostat

2.Coverslip (22 x 40 mm/ 7.The specimen disc was placed in the orientable specimen

24 x 60 mm) head

8.The tissue was trimmed at 10 microns thick and sectioned at

3.Microtome blade Figure 27: The apparatus of

4. Forcep frozen section. 5 microns.

9.The tissue section was placed onto a labeled slide and

5. Brush

placed into a preheated 10% formalin

6.Applicator stick 10.This part needs to be done immediately

7.Coplin jar C. Tissue was stained using rapid Haematoxylin and Eosin

Figure 28: The inside view of

frozen section machine

equipment

1.Cryostat: Slee Mainz MEV

2.Oven: Memmert

result

1.Tissue block from embedding Table 9: The time setting of each reagent for frozen section in staining procedure. Source from 8

laboratory manual UiTM Puncak Alam

Figure 29: Tissue block after embedding.

Source from Dr. Stephen peters, IHC World

2. Tissue section

Figure 30: Tissue section after sectioning.

Source from Dr. Stephen peters, IHC World

3. Stained tissue slide

Figure 31: Stained tissue slide after staining.

Source from Dr. Stephen peters, IHC World

frozen section

D. The slide was mounted Problem solution

E. Microscopic examination was performed. Ice crystal artifacts Faster the freezing to

due to slow freezing get less tissue

F. Cleaning process of tissue damage

1.After done, the embedding medium was left at room

Overfreezing can Warm up the block by

temperature to ensure it would melt. cause section to have pressing on it with your

2.The residual tissue was placed in 10% formalin. holes finger and polishing it with a

3.The cryostat was cleaned. couple more rotations of the

blade to produce friction.

Flow chart 4: The procedure of frozen section.

Table 10: Troubleshooting of frozen section

CONCLUSION

The frozen section method by using the cryostat was learnt

Conclusion

Zakiah & Nazirah

To conclude, microscopic analysis of cells and tissues requires the preparation of very

thin high quality sections mounted on glass slides and appropriately stained to demonstrate

normal and abnormal structures of the tissue. The accuracy for the frozen section is much

higher but need to be aware of its indication and limitations. All of the processes must be done

correctly by following the procedures and methods with focus and effectiveness. In tissue

grossing, ensure the size of the specimen must fit with cassettes. Then, assure the right

reagent or chemical during tissue processing. In the embedding process, the tissue needs to

be in the right orientation. Next, ensure the microtome is set up 10 microns for trimming and 3

microns for sectioning. However, the block should be freezed before sectioning. Moreover,

alert in timing during H&E stains to avoid overtime staining. Lastly, bubbles should be avoided

during slide mounting. The perfect results allow pathologists examined under microscopes to

characterize the details of the cells in the tissue.

9

References

1.Anatomic pathology instruments & equipment. (2020, December 1). Diapath. Retrieved December

20, 2021, from https://www.diapath.com/blogarticle/empty-0/tissue-sectioning-9

2.Dr. Peters, S. (n.d.). Frozen Section Methods and Techniques. IHC WORLD. Retrieved December

20, 2021, from http://www.ihcworld.com/_protocols/histology/frozen_section_technique_1.htm

3.Giri, D. (2018, November 5). Hematoxylin and Eosin (H&E) Staining : Principle, Procedure and

Interpretation. LaboratoryTests.org. Retrieved December 20, 2021, from

http://laboratorytests.org/hematoxylin-and-eosin-staining/

4.Gross Examination: General Considerations. (n.d.). LabCE. Retrieved December 20, 2021, from

https://www.labce.com/spg696387_gross_examination_general_considerations.aspx

5.Immunohistochemistry (IHC) Troubleshooting Guide. (2020, July). Boster Bio. Retrieved December

20, 2021, from https://www.bosterbio.com/protocol-and-troubleshooting/ihc-troubleshooting

6.Mohd Nornizam (2021). Laboratory manual of Histological Techniques. Universiti Teknologi Mara.

7.Ravikumar, S., Surekha, R., & Thavarajah, R. (2014, March 10). Mounting media: An overview.

Journal of Dr. NTR University of Health Sciences, 3(5), 1-8. 10.4103/2277-8632.128479

8.Sim, J. (2018, December 19). What is a Frozen Section? Geneticist Inc. Retrieved December 20,

2021, from https://www.geneticistinc.com/blog/what-is-a-frozen-section

9.Wallace, J. (2011, October 1). Frozen section procedure. Pathology Outlines. Retrieved December

20, 2021, from https://www.pathologyoutlines.com/topic/breastfrozenprocedure.html

The words you are searching are inside this book. To get more targeted content, please make full-text search by clicking here.

1.FARAH FAIHANA BINTI SUHAIMEE (2020473322)

2.FATIN NUR SYAZWANI BINTI ALIAS (2020834134)

3.NUR ATISYA FARHANA BINTI MAT ZALAMI (2020866392)

4.NUR IFFAH NADIAH BINTI ILIAS (2020819734)

5.NURUL NAZIRAH BINTI RUSMAN (2020621516)

6.SITI NURZAKIAH BINTI JA'AFAR (2020846784)

Discover the best professional documents and content resources in AnyFlip Document Base.

Search

HS2413A STEP BY STEP HISTOLOGY (GROUP 5)

- 1 - 11

Pages: